We live in times when almost every product can be bought cheaper. But very frequently the reduced cost also means reduced quality. Using materials that conform to all necessary standards of the profession should be a certainty – unfortunately, we see that it is not always so.

The quality of a product is important in all aspects of live, but it has to receive special attention when health is at stake. Our mission is to provide a quality, functional and aesthetically pleasing prosthetic replacement for every end user – dentist and his/her patient.

Naturaldent refuses to create savings by substituting for cheaper materials of questionable quality. Of course, we are always aware of the importance of competiveness and our final price. For this reason – through strategic negotiations with our suppliers, strict manufacturing control and realistic business planning – we strive to always be competitive. Our vision is to become the largest dental laboratory in the region, as well as a reliable partner to every dentist who places the health and satisfaction of his/her patients first.

Your trust is our largest capital – trust in our products, our expertise and responsibility. This is a capital we have been building for 15 years – still, every day with each new task we approach your works as if you were our first and only client.

Our success is founded on reputation. As a business team, we aim to support this cause daily through responsible work and client relations. It is our opinnion that in the long run, our quality and consistency works in your best interest as a dentist and of course the best interest of the end user – your patient.

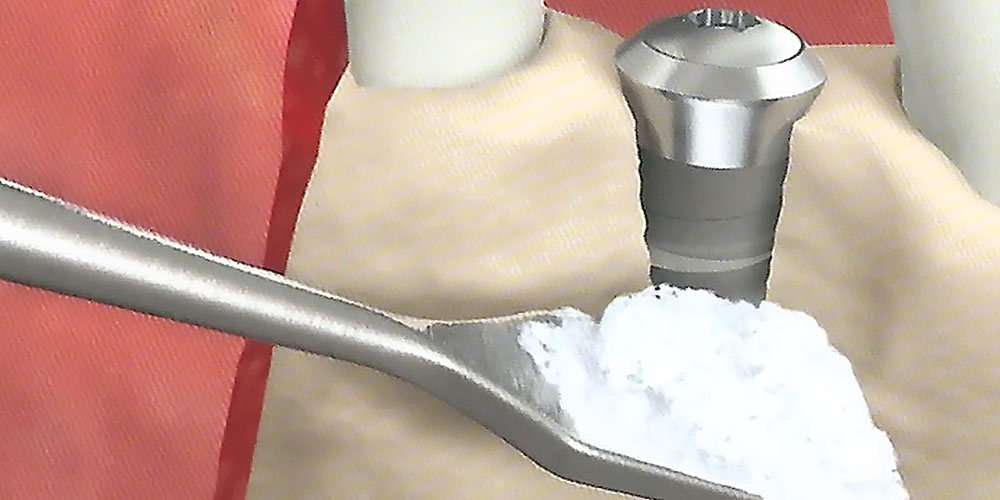

Production planning department – creation of precise gypsum models from dental impressions. For the creation of quality models which are a foundation for quality products we use only certified materials from respected world manufacturers, along with continuous controls of procedures and quality of created models.

Modeling department – after passing the first quality control, the gypsum model is used to precisely model the future metal construction in wax for future creation of products such as bridges, crowns, abutments, modified crowns, etc. Along with control of the prior step, a flawless creation of wax constructions is crucial, due to the fact that the metal foundation is cast based on this model.

Mobile prosthetics and metal department – Precisely cast gypsum and wax models provide a secure foundation on which metal constructions can be built, or elements of mobile prosthetics installed. We create full or partial BPS prosthesis including gingival individualization in the labio-buccal area, and the modelation of the palatinal area of the prosthesis. If desired, we also perform individualization of teeth. Besides technical knowledge, further work demands a dose of artistic spirit in order to create a truly natural looking product.

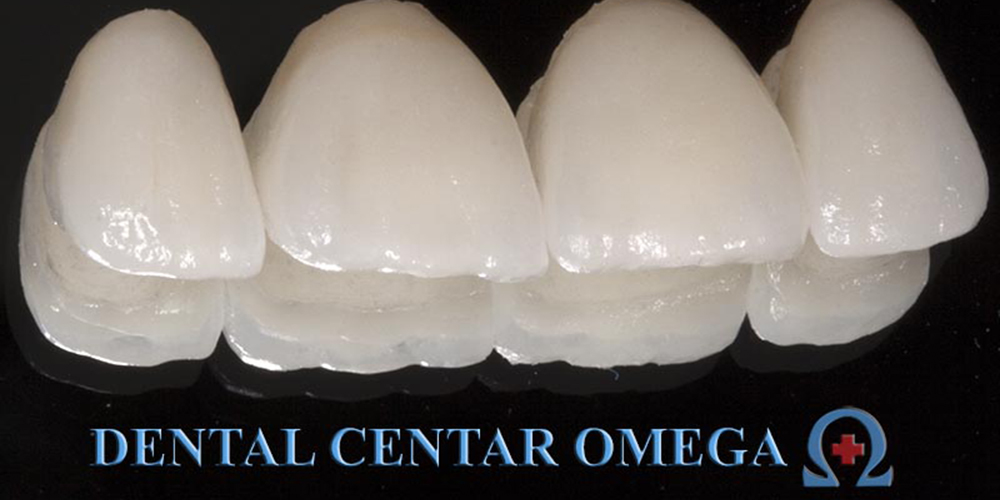

Ceramics/aesthetics department – speaking of art, we cannot forget our most creative department, ceramics and aesthetics. Regardless of the technical perfection of the dental product thus far, without their expertise and artistic spirit, the end product will not satisfy the discerning client. Human teeth are as individual as human faces. Using modern technology for sampling teeth colors, using top quality ceramic materials and – of course – adding their artistic touch interlaced with years of experience, our artists turn the white foundation into natural looking teeth which perfectly complement the mouth of every patient.

Metal framework department – Using modern technology we construct light metal prosthesis using metal alloys without Nickel (an allergen for some patients). The advantage of metal framework prosthetics is a final product that is lighter, thinner (0.6 mm in comparison to the classic acrylic prosthesis of 4-5mm) and stronger than classic prosthesis. Besides, the very thin structure allows the material to be used both in mobile and combined prosthetics, providing for an all-together more refined production.

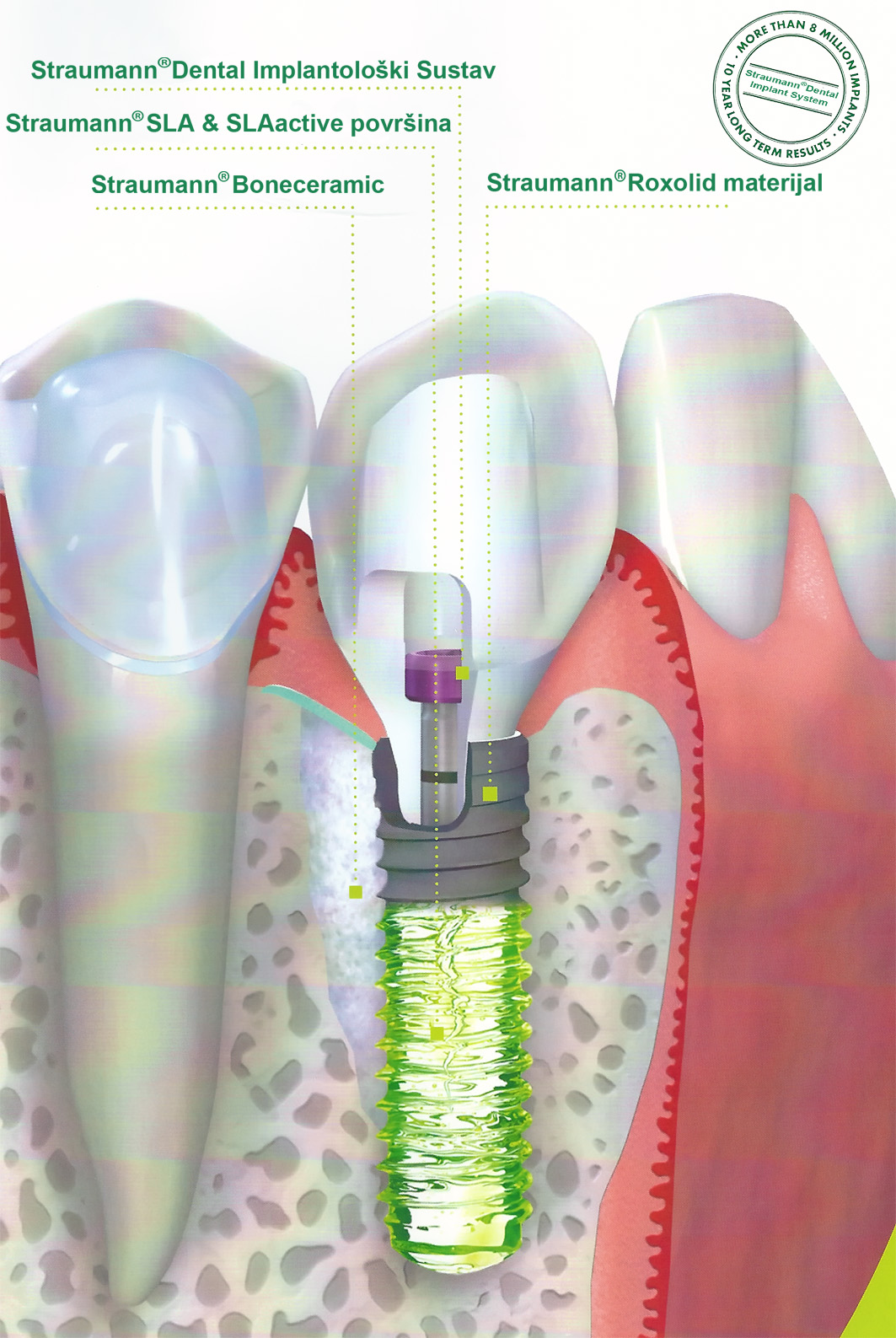

CAD/CAM department – The most modern department in our company, using technology which places us years ahead of most dental laboratories in Croatia is certainly our CAD/CAM technology department. Powerful computers, digital scanners, zirconium and titan milling machines with a precision of several microns sounds like technology until recently found only in the cutting-edge aeronautic, military and space industry. Today, this same technology is available for the manufacture of prosthetic works. Top of the line KaVo CAD/CAM technology ensures that your products will fit into the prepared place the first time – every time. As with all other materials used by Naturaldent, the used materials (zirconium and titan) are shipped with certificates of biocompatibility, ensuring the safety of your patient’s health.

Administration and delivery – of course, in order for the whole system to function perfectly, it is necessary to deliver impressions from the various laboratories in a safe, secure and timely manner, ensure that all requests and desires of the dentist have been properly relayed to appropriate individuals and finally, ensure that the completed products arrive back into the right hands on time. Each product leaving our laboratory has to be accompanied by all necessary certificates and documentation, and once it leaves our company, a reliable and precise delivery is a vital link.

Management – as in many other aspects of our business, Naturaldent is one step ahead of others in the very organization of our business. Strict DNV ISO 9001:2008 quality standard demands are reflected in every step of the production proce4ss, from quality control and tracking of incoming materials to prescribed production processes and proper product packaging.

We at Naturaldent realize that the foundation of every business is our relationship with the clients. The management continuously works on improving these important business relations and informing them of new products, innovations, improvements and special conditions.

We consider the feedback from our clients – dentists – to be the best way to improve our business. We encourage communication through opening more channels of communication and ways to properly analyze and apply them.

Exclusive line products: